India accounts for 15% of the total world production of the fruit crops and ranks second with the production of 98 Mt in the Year - 2017-18. The Grading of fruits on the basis of size and shape is important as it adds the value to the product and gives better economic gains to the producer.

At present, the fruits are graded manually which is labor intensive and time consuming and even the operation is affected due to non-availability of labors during the peak seasons. Besides, the manual grading has a wide variation in the sizes of the graded fruits. In view of the above considerations, the ICAR-Central Institute of Agricultural Engineering, Bhopal designed and developed a commercial scale multi-fruit grader suitable for grading the different types of spherical-shaped fruits. The fruit grader consists of a grading unit, horizontal belt conveyor and feeding unit.

The grader has provision to separate fruits into five grades by adjusting the flap spacing between 30 and 145 mm. The grader is operated by a 0.74 KW single phase motor. The overall grading efficiency of the grader is 95-97 % for apple, sweet lemon, orange and sapota fruits. The capacity of the grader is 5 t/h at the grading conveyor speed of 7 m/minutes and there is no damage to the fruits while grading. The cost of the grader is Rs. 1 lakh. The cost of operation and energy consumption of the grader are Rs. 0.80/kg and 0.30 KW/T, respectively.

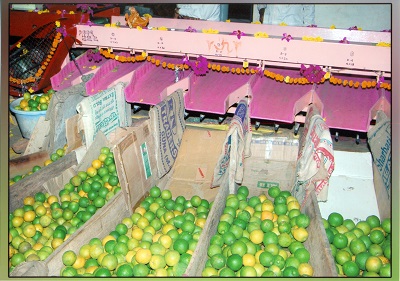

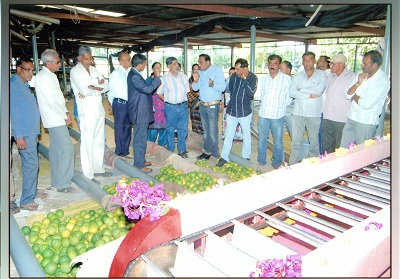

Shri Sridhar Patidar, grower of Mousambi and safed musli was provided with the developed grader installed at the Vrindavan Fruit Garden & Nursery, Jotpur, Madhya Pradesh, India for the commercial grading of sweet lemon in seven grades. Shri Patidar runs the grader for grading of 1,250 tons of sweet lemon annually, which was produced from 65 acres of area under cultivation in Jotpur, Dhar Farm. One person can grade 450 kg/day of fruit manually, hence, 2778 man-days was required for the grading of 1,250 tons of sweet lemon annually. The total cost of the labor @ Rs. 400/man-days was calculated to be Rs. 11.12 lakhs for grading of 1,250 tons of sweet lemons.

On the other hand, the capacity of the grader has been 5 t/h, which could grade 1,250 tons of sweet lemon in 32 days considering 8 hours of operations per day. This could save 98.84% of time and labor with efficient grading. The cost of operations of the grader has been worked out as Rs. 800/ton which makes a total cost of Rs. 10 lakhs for grading of 1,250 tons of sweet lemon. Hence, a saving of Rs. 1.12 lakhs in cost has been experienced by using the grader annually. The cost of sweet lemon without grading was Rs. 20/kg; however, the average price obtained for graded sweet lemon was Rs. 25/kg. Therefore, the net benefit from 1,250 tons of graded sweet lemon was Rs. 62.50 lakhs annually.

The Commercial Fruit grader has been in operation in the Vrindavan Fruit Garden & Nursery, Jotpur for the grading of sweet lemon for the last five seasons. Hence, a saving of Rs. 5.6 lakhs in labor cost has been achieved in the five years. The graded uniform size sweet lemon fetched more prices in the market and earned benefit to the farmer. Thus, the overall benefit from the marketing of graded sweet lemon in five years using the ICAR-CIAE Commercial scale Fruit Grader for the farmer is Rs. 3.12 crores apart from considerable saving in time and labor with efficient grading. The Break Even Point, Return on Investment and Pay Back Period of the fruit grader are found to be 30 tons, 496% and 0.045 years, respectively.

(Source: ICAR-Central Institute of Agricultural Engineering, Bhopal)

Like on Facebook

Subscribe on Youtube

Follow on X X

Like on instagram