Background:

The Paddy is grown world-wide mostly by hand transplanting of seedlings in puddled soil. The farmers in many parts of the world are using different types of paddy transplanters that require mat-type seedlings.

Due to the complexity in operation of machine, its high cost, necessity of growing mat type seedlings & variation in efficiency of machine in different kinds of soil and also in different fields the pace of adoption of the transplanter is very slow in India.

The Direct Seeded Paddy (DSP) cultivation is picking pace with the development of some improved varieties as well as on account of development of effective weedicides. At present, the farmers are slowly adopting the DSR (Direct Seeded Rice) technology and are broadcasting dry seeds of paddy in well-pulverized soil. The mixing of seed in soil upon broadcasting by tillage equipments result into dispersal of seed at variable depth in randomized pattern, accounting to poor germinations of seed followed by poor crop establishment.

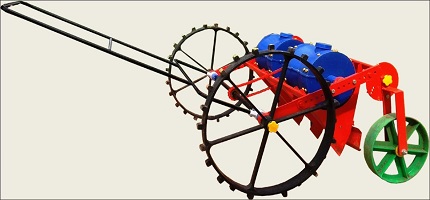

The Rice-Wheat Seeder equipment is capable of regulating the seed rate and put the seeds in soil at desired depth with proper maintenance of plant-to-plant distance ranging from 8-15 cm within the row. This character of machine helps the users to grow paddy in well defined row spaced at 20 cm and, thus, leaves the farmers with opportunities of using the mechanical weeding tools in between two consecutive rows for weeding.

The scientist of College of Agricultural Engineering, Dr. Rajendra Prasad Central Agricultural University, Pusa developed the Rice Wheat Seeder equipment and the same is being manufactured by M/s Bihar Maa Durga Agro. Industries Pvt. Ltd., Pandaul, District Madhubani, Bihar.

Features of Equipment:

|

Effective width of equipment |

: |

0.96 meter |

|

Recommended working speed |

: |

1.8 – 2.25 km/h |

|

Effective field capacity |

: |

0.40 – 0.50 ha/day |

|

No. of labor required |

: |

02 |

|

Seed capacity of each drum |

: |

5 kg |

|

Recommended filling weight in drum |

: |

3 kg |

|

No. of Drums/Machine |

: |

02 |

|

No. of row of holes on each drum |

: |

04 (two rows on each side) |

|

No. of furrow opener & seed collector |

: |

04 |

|

No. of depth control wheals |

: |

02 |

|

No. of depth control settings hole |

: |

03 |

|

Minimum and maximum achieved depth for seeding |

: |

1.0 cm (Min.) & 3.0 cm Max.) |

Field Performance of Equipment:

The machine was evaluated in paddy and wheat crop in the research farm of Dr. Rajendra Prasad Central Agricultural University (DRPCAU), Pusa as well as in Krishi Vigyan Kendra farm of Bihar Agricultural University (BAU) Sabour, Bhagalpur.

|

Particulars |

On Farm Trail at DRPCAU Pusa |

On Farm Trail at BAU, Sabour |

|

Location |

Research plot of DRPCAU, |

Research plot of KVK Sabour, Bhagalpur |

|

Crop |

Paddy |

Paddy |

|

Variety |

“Rajendra Saraswati” |

“Rajendra Sweta” |

|

Method of Cultivation |

Seeding of dry seeds in well pulverized soil |

Seeding of dry seeds in well pulverized soil |

|

Field preparation |

By Rotavator in two passes |

By Rotavator in two passes |

|

Date of seeding/harvesting |

15.06.2018/07.10.2018 |

24.06.2018/05.11.2019 |

|

Seed rate (kg)/ |

22.0 /4000 |

22.0/3880 |

Performance in Farmers Fields:

(Direct seeding by Equipment Vs Transplanting)

The direct seeding of paddy by Rice-Wheat Seeder was evaluated against the transplanting method in farmer’s field. The enhancement in yield by the equipment was found in range of 5 - 25 % at different locations.

|

S. No. |

Farmers’ Name & Address |

Variety |

Yield (kg/ha) by Rice-Wheat Seeder |

Yield (kg / ha) by Transplanting Method |

% gain in yield |

|

1. |

Sunil Kumar, Muradpur, |

Rajendra |

3760 |

3295 |

14.11 |

|

2. |

Rajan Kumar Ray, |

Rajendra |

6500 |

5200 |

25 |

|

3. |

Sailendra Pratab Singh, |

Gangotri |

4549 |

3960 |

14.87 |

|

4. |

Pankaj Kumar, Birnoudh, |

Rajendra Sweta |

3630 |

3350 |

8.35 |

|

5. |

Pramanand Gupta, |

Rajendra |

3970 |

3420 |

16.08 |

|

6. |

Amarnath Kumar, Village - Rasalpur, Dumara, Sitamarhi |

Smarth |

3800 |

3680 |

3.26 |

|

7. |

Ajay Kumar Singh, Basant Patti, Purnahiya Seohar. |

Sawrna |

4485 |

4179 |

7.32 |

Cost of Cultivation (Direct seeding by Equipment Vs Transplanting):

|

S. No. |

Farm Operation |

Cost in DSR by Rice-Wheat Seeder |

Cost by Transplanting Method |

Net Saving over Transplanting |

|

1. |

Land preparation |

4500.0 |

4500.0 |

- |

|

2. |

Seedling raising |

- |

1200.0 |

1200.0 |

|

3. |

Puddling |

- |

3750.0 |

3750.0 |

|

4. |

Irrigation |

1700.0 |

3750.0 |

2000.0 |

|

5. |

Machine operation |

1700.0 (two labour) |

- |

(-) 1700.0 |

|

6. |

Transplanting |

- |

6000.0 |

6000.0 |

|

7. |

Chemical weeding |

2000.0 |

1200.0 |

(-) 800.0 |

|

|

Net Saving |

Rs. 10,450.0 |

||

Dissemination and Adoption:

The equipment has been demonstrated at many places inside and outside Bihar by the manufacturing company, KVKs and State Government Officials for wider use. The equipment was included under hybrid promotional plan of a reputed company named “Pioneer Seeds”. On using the Rice-Wheat Seeder equipment for line sowing of rice and wheat, the farmers of Chhattisgarh, Madhya Pradesh, Jharkhand, Uttar Pradesh and Bihar have realized the higher yield in wheat crop too in comparison to the well-adopted practice of growing wheat by the broadcasting method.

|

S. No. |

Name of Equipment Purchaser/User |

Quantity |

Area under demonstration in ha |

|

1. |

Department of Plant Breeding, DRPCAU, Pusa |

01 |

0.40 |

|

2. |

Department of FMPE, CAE Pusa |

01 |

0.50 |

|

3. |

KVK, BAU, Sabour |

02 |

2.0 |

|

4. |

KVKs, Barh, Patna |

01 |

0.30 |

|

5. |

KVK, Seohar |

02 |

1.0 |

|

6. |

KVK, Vaishali |

01 |

1.25 |

|

7. |

KVK, Khodabandpur |

01 |

0.40 |

|

8. |

KVK, Arah, Bojpur |

01 |

1.25 |

|

9. |

KVK, Buxar |

01 |

0.20 |

|

10. |

KVK, Latehar, Jharkhand |

01 |

0.35 |

|

11. |

Borlauge Institute of South Asia (BISA) |

01 |

0.40 |

|

12. |

Pioneer Seed |

512 |

250.0 |

|

13. |

D.A.O., Supaul |

01 |

0.40 |

|

14. |

Agricultural Specialists, Government of Bihar |

01 |

1.0 |

|

15. |

Hon’ble Agriculture Minister, Bihar |

01 |

0.20 |

Feedback:

All the users were satisfied with the performance of machine and most of them had realized better yield of paddy in direct seeding than the transplanted rice under proper weed control.

Due to excessive weed, deficient moisture and faulty operation of machine at some places, the results were not very much encouraging. However, all the users were of view that by the use of the rice-wheat seeder the paddy can be successfully cultivated with net saving of about Rs. 4,000 - 5,000 / acre. The machine was found easy in operation, adjustment and maintenance.

(Source: College of Agricultural Engineering, Dr. Rajendra Prasad Central Agricultural University, Pusa, Samastipur, Bihar)

Like on Facebook

Subscribe on Youtube

Follow on X X

Like on instagram