Custard Apple is widely grown fruit crop in Rajasthan, Andhra Pradesh, Karnataka and Rajasthan states and has good potential for value addition for socio-economic upliftment of farmers. Extraction of pulp is a major constraint in processing of custard apple fruits. Development of enzymatic browning within an hour of pulp extraction, bitterness, unpleasant repulsive off-flavour in the pulp on heating beyond 650C and presence of gritty cells are problems encountered during processing of fruits.

For the first time scientists at the Maharana Pratap University of Agriculture and Technology (MPUAT), Udaipur have developed technology as well as machine for Browning free mechanised pulp extraction from the Custard Apple. Custard Apple is an important underutilized fruit cultivated in parts of Rajasthan. Browning is a change in colour of pulp due to enzymatic oxidation and the brown pulp is not edible and fetches no price in the market. Custard Apple pulp is used to prepare Ice cream, Rabdi and beverages.

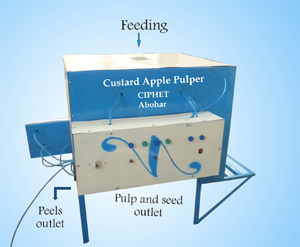

The technology as well as machine has been developed at the Department of Horticulture, Rajasthan College of Agriculture (RCA), MPUAT, Udaipur under the National Agricultural Innovation Project (NAIP). NAIP is the World Bank funded project of Indian Council of Agricultural Research, New Delhi. The machine has two parts. First part scoops out the pulp with seed from fruit leaving behind the peel (i.e. pulp extraction). The second part separates the seed from the pulp which can be stored for up-to one year. The machine has been designed and developed by Central Institute of Post-Harvest Engineering and Technology, Abohar, one of the consortium partners in the NAIP Sub project on “A value chain on commercial exploitation of underutilized fruits of tribal zones of Rajasthan”.

Prof. O.P. Gill, Vice Chancellor, MPUAT, Udaipur said, “The technology will offer livelihood security to tribal people and help in conservation of underutilized fruit species of Rajasthan apart from increasing farmer’s income and living standards of custard apple growers”.

Dr. R.A. Kaushik, Professor and Head, Department of Horticulture and Dr. Sunil Pareek, Assistant Professor, Department of Horticulture, MPUAT, Udaipur have developed this new technology. Dr. Kaushik said, “Traditional pulp extraction is non hygienic, less shelf life, poor in quality and it is done manually so it is costly. This new technology is very useful as it reduces the cost of pulp extraction and enhances the quality of pulp”.

Tribal people, who are growing custard apple, transporters, food processing industries (Dairy including Ice-cream, Rabdi), Beverage Industries( Juices and milk shakes), Event organizers (Marriages, Birth days and Kitty parties) and Halwais (sweet makers) will be benefited from this technology. To harvest the benefits of this technology to the remotest users, the MPUAT has licensed the technology of browning free mechanised pulp extraction from the Custard Apple for commercialization to two companies in Gujarat namely Santram Ice-cream and Snacks, Anand and Deep Fresh Frozen products, Navsari through Business Planning and Development Unit (BPDU) under Public Private Partnership (PPP) mode.

(Source: NAIP-Mass Media Project, DKMA with inputs from Department of Horticulture, MPUAT, Udaipur and DMAPR, Anand)

फेसबुक पर लाइक करें

यूट्यूब पर सदस्यता लें

X पर फॉलो करना X

इंस्टाग्राम पर लाइक करें